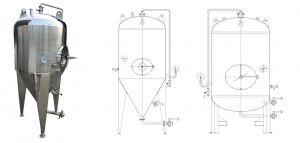

Brite Tank

Brite beer tank’s primary purpose is the maturation of beer. They are often used to chill, carbonate and age the beer into the well-rounded craft beverage.

Mordern commercial breweries often utilize single-walled stainless steel brite tanks which can be reused indefinitely, are impregnable to odors and discoloration, and can be sanitized easily.

Total Vessel only uses sanitary fittings and hardware. See below details, many sizes are possible, please contact us if you don’t see the size you need.

Total Vessel designs and manufactures sharp, well polished brite tanks to ensure every customer’s expectation.

Whether you need smaller, compact brite tank for serving directly or even a large-scale tank, we have the ability to build from 1BBL up to 300BBL.

- cylindrical pressure tanks with dished bottoms

- available in two designs: with (BTI) and without insulation (BTX)

- equipped with laser welded heat exchangers, separate cooling zones can be individually controlled

- adjustable tank feet

- construction material: SUS304 or SUS316L

- external finish can be mechanical polishing, brushed, sand blasting or electropolishing, internal surface is polished with roughness below 0.4μm

- inlet connection

- safety valve

- oval manway

- level indicator

- removable CIP tube with spray ball

- pressure gauge

- digital thermometer

- bottom drain port

- sample port

| Code | Volume (L) | Inner tank size (DxH)mm | Overall Height (mm) |

| BTX BTI |

500 | Φ850×800 | 1725 |

| 1000 | Φ1100×900 | 1950 | |

| 2000 | Φ1300×1300 | 2500 | |

| 3000 | Φ1500×1500 | 2800 | |

| 5000 | Φ1800×1650 | 3100 | |

| 6000 | Φ1900×1800 | 3350 | |

| 8000 | Φ2100×1950 | 3600 | |

| 10000 | Φ2300×2000 | 3800 | |

| 20000 | Φ2600×3400 | 5350 | |

| BTX is without insulation, BTI is with insulation | |||