Cross-flow filtration system

Total Vessel has combined our experience with our unmatched engineering and innovative capabilities to create beer filtration systems to meet the filtration requirements of the brewing industry.

Beer filtration with ceramic membranes

Total vessel has combined our experience with our unmatched engineering and innovative capabilities to create beer filtration systems to meet the filtration requirements of the brewing industry.

Ceramic membranes-membrane technology designed for beer filtration

The ceramic membranes from the centrepiece of this cross-flow filtration. The material is absolutely foodneutral and can be regenerated again at any time in the filtration system.

The service life of the membranes is at least three years. The result: purest beer quality – brewed in a way that is sustainable and reduces costs.

Durable ceramic membranes

Advantages of ceramic membranes in cross-flow filtration:

- completely inert material

- free to choose the right pore size for an optimum filtration

- operationally safe

- long lifetime

- high temperature range, can be sterilized with steam

- high mechanical stability

- very good cleanability

- full ph range 0-14

- standard cleaning agents: NaOH, HNO3 and booster

- acid and base resistant, solvent resistant

- can be generated

- no problems with back flushing

- wear resistant

- robust against pressure and temperature

- constant flux rate of filtrate over the complete cycle

- minimum operational costs

- short installation and start-up times, due to pre-assembling

Application in beer filtration:

- non-alcoholic beer production

- beer clarification

- yeast recycling

- tank bottom beer recycling

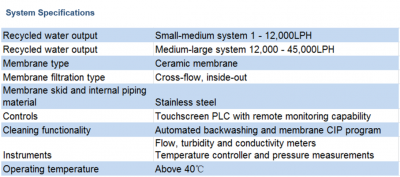

TV-CMF Series cross-flow filtration systems

Total Vessel’s TV-CMF series crossflow filtration systems utilize ceramic membranes to produce consistent, high quality, bright beer over long sustained runs. An inert CO2 blow down feature minimizes beer loss by recovering filtered beer at the end of each run and an onboard CIP tank reduces system down time with quick and effective membrane cleaning.

We provides a range of compact and scalable systems which capacity from 1 LPH up to 45,000 LPH.

System Benefits

- fully automated systems reduce labor costs

- high beer yields

- fast changeover between beer varieties

- modular, easily expandable system design

- utilize ceramic membranes

TV-CMF series systems are skid mounted, have an energy efficient design and a small system footprint. They are available with multiple membrane configurations and are expandable to meet the requirements of most filtration applications. Multiple units can run in parallel to meet high flow rates.

Total Vessel’s TV-CMF series crossflow filtration system is a waste-free beer filtration process. Filter aids can be completely omitted. Sustainable and at the same time cost-cutting process management is thus supported at the critical point. In parallel with this, the process fulfils the consumer desire for crystal clear beer in permanently consistent quality. The beer quality remains consistently high with ceramic filtration.